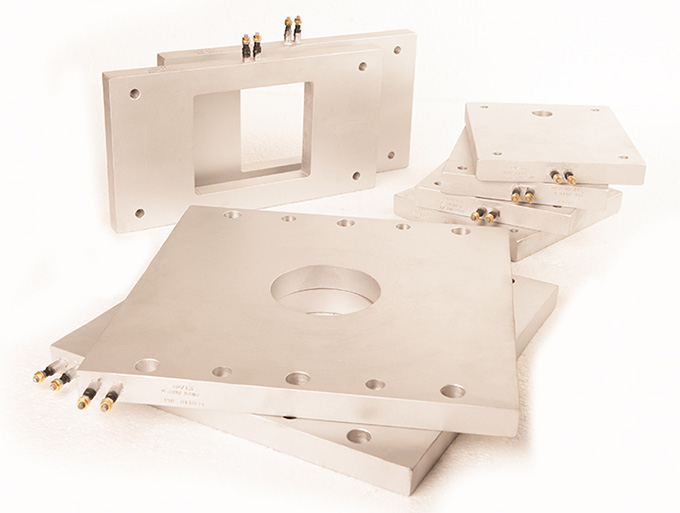

Soloheat Cast Aluminium / Aluminium Bronze Industrial Heating Elements

Soloheat specialise in the manufacture of Cast Aluminium and Cast Aluminium Bronze heaters.

Based in Gloucestershire, we are the only foundry in England to specialise in the manufacture of Cast Alloy Industrial Heating Elements.

Typical applications

Cast alloy heaters are strong and robust and are best used in processes requiring higher heat with greater reliability and longer life than other types of heating element. Transfer pipes, extrusion / injection moulding barrels and extrusion die blocks are commonly fitted with cast alloy heaters.

Features

- Potential power density greater than other types of band heater.

- Highest application temperatures available > 600oC / 1112oF

- Recommended application temperatures > 300oC / 572oF

- Round heater Minimum / Maximum diameter = 10mm id / 800mm id

- Round heater Minimum / Maximum width: 20mm / 800mm

- Flat heater minimum length = 60mm

- Flat heater minimum width = 20mm

- Minimum heater thickness = 16mm (dependant upon other dimensions)

- Maximum Power densities:

- Aluminium heaters <40 watts / inch² (6.2w/cm²) – 400 Degrees Celsius

- Aluminium bronze heaters <50w/inch² (7.75w/cm²) – 550 Degrees Celsius

Air Cooled cast alloy heaters

Cast Aluminium finned heaters are most often fitted on extruder barrels under cowls. Centrifugal fans are commonly used to blow air between the fins to offer accurate temperature control. The fins can be manufactured on the inside or outside diameter of the heater,

depending on the machine type and existing heaters fitted. We can manufacture the cowls and ducting to shroud our finned heating elements.

Water cooled - Cast Alloy Heater Coolers

Cast alloy Heater cooler combinations are used where water is required to control processing temperature. Cooling jackets / mandrels are also available without a cast in element. Cooling tube available in stainless steel and Incoloy in below sizes:

- Metric (o/d in mm):

6, 8, 10, 12, 15, 20 - English (o/d in inches):

3/8”, ½”, 1”

Various wall thicknesses, material specs and seam / seamless tube options are available.

The electric element and water pipe is cast into the alloy body of the unit to offer accurate temperature control of the barrel or heated body. Compression fittings or cast in connectors are available as options

Termination

Cast Heaters are terminated according to customer requirements. These range from IP65 dust/ moisture proof housings, to the more commonly fitted two / three pin plugs, terminal boxes, block terminals, screw terminals, or metal braided leads.

We also offer a range of bespoke terminations developed over many years, most of which can be offered to clients for their own applications.

Patterns and Dies

Soloheat hold a large stock of patterns and dies for Cast Alloy Heaters. When required, we have in-house pattern makers and pattern shop to manufacture new or modify existing patterns and tooling. We can sometimes use clients samples to reduce pattern

costs.

Cast alloy heater delivery times

Typical lead time for Cast Heaters = 2 – 3 weeks for small items, 4 – 6 weeks for more complex units. We confirm manufacturing lead times at the time of quotation.

To order or enquire

Click here to download our Cast Heater survey sheet template

Alternatively, e-mail us as much of the following info as possible:

- Inside Diameter (round heater)

- Outside Diameter (round heater)

- Length overall (flat heater)

- Thickness (flat heater)

- Width overall (round and flat heater)

- Wattage

- Voltage

- Termination type (include length if leads)

- Number of Holes / cut outs

- Cooling fins req’d (state which surface in finned)

- Water cooing req’d (state tube size and type of connectors req’d if any)

- Application of heater

- Qty of heaters required

- Cast Alloy Heater warranty

- Please refer to our term and conditions regarding warranty. (Section 6

In a hurry? Complete our contact form and we will get back to you ASAP - click here